Scalers & Curettes - EverEdge 2.0

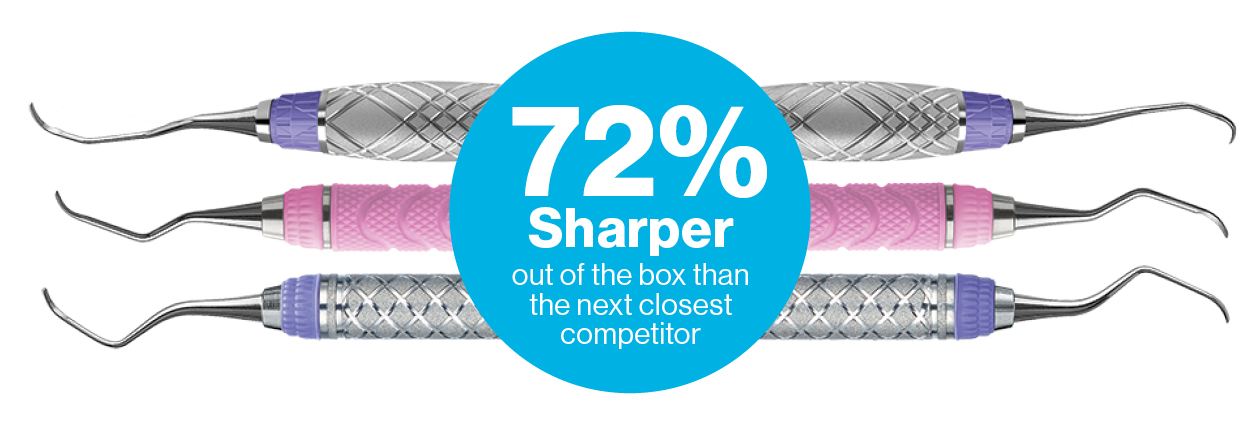

Our EverEdge™ 2.0 Technology is unlike anything you’ve experienced before in a scaler blade. We’ve combined state-of-the-art technology to create a superior stainless steel that keeps your scalers and curettes sharper longer. Sharp scalers improve performance by allowing for fewer repetitive debris removal strokes and, fewer strokes reduces treatment time and results in more patient comfort. Every clinician loves a brand-new sharp scaler and EverEdge 2.0™ Scalers are not only sharp out of the package – they stay sharp longer. That means less frequent sharpening, less hand fatigue, and greater comfort throughout the day.

AND After 500 Strokes It’s...

WHY EVEREDGE™ 2.0?

New Finely-Honed Finish

EverEdge™ 2.0 Technology uses a new, optimized heat control process in order to maintain the hard,sharp edge. This heat control, plus several manufacturing intricacies in our proprietary process, provide the durability needed for effective procedures and continued use.

Stays Sharper Even Longer

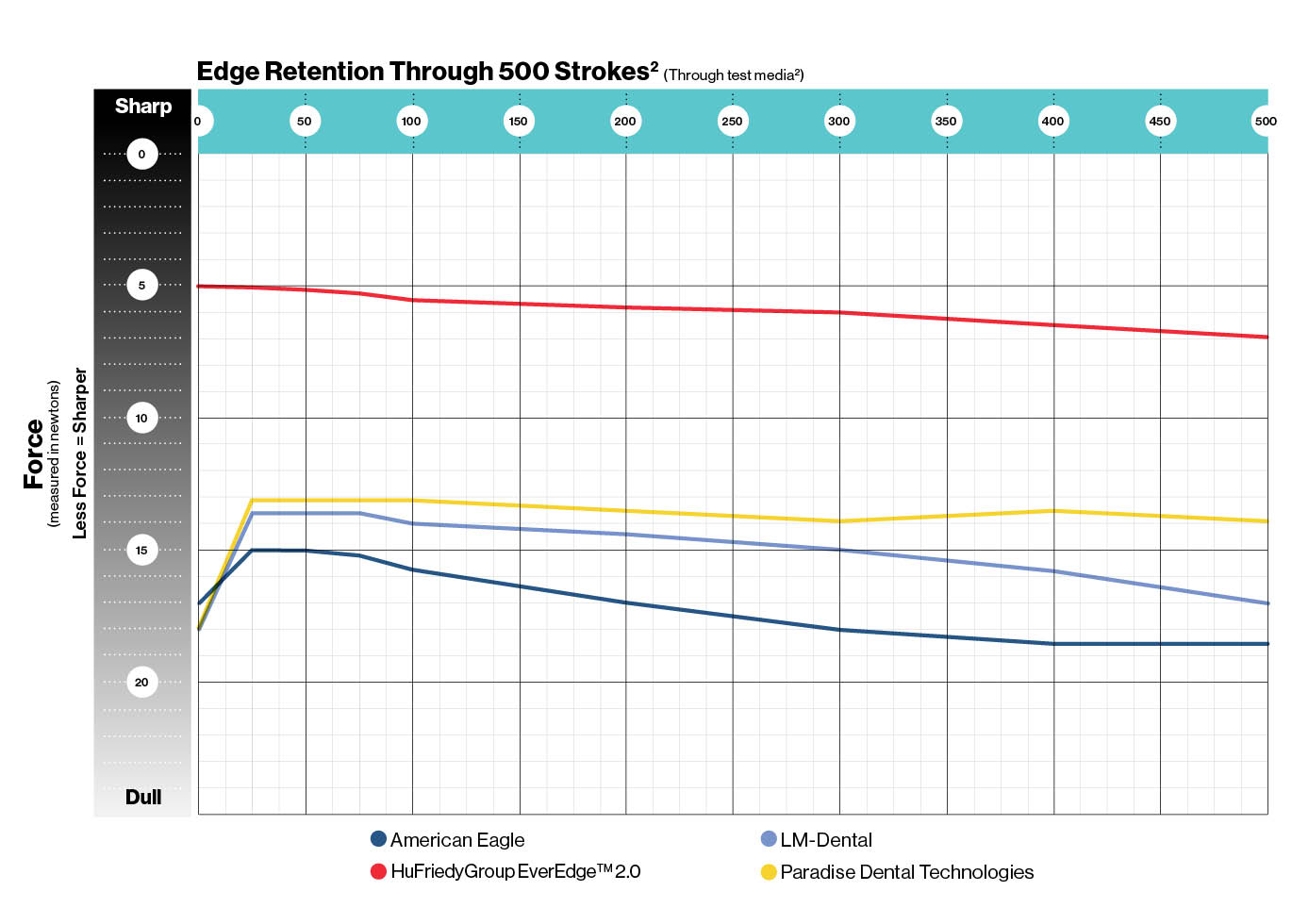

EverEdge™ 2.0 Scalers are sharper than ever. Using an enhanced finishing process, Our professional artisans are creating edges that are scientifically measured to be over 60% sharper than the next closest competitor. Less force means easier, more comfortable scaling for the clinician and patient.

Uncoated Performance

Withour EverEdge™ Technology, our proprietary processing ensures that the superior edge retention & wear characteristics of EverEdge™ 2.0 Scalers will last the entire life of the instrument. Since it’s not a superficial coating, these characteristics can’t be sharpenedor scraped away. EverEdge™ 2.0 Scalers can be resharpened at any point to extend their life.

Revolutionary Testing System

We have invested in a custom blade evaluation system to ensure clinicians are receiving the sharpest possible instruments. Blades from every batch of EverEdge™ 2.0 are tested right off the factory line to confirm that the sharpness value remains in our target range, averaging five newtons of force required to cut the test material.

EVEREDGE™ 2.0 HANDLE STYLES

Harmony™

Ergonomic Scaler Handle

Our Harmony™ Ergonomic Scaler and Curette handle is scientifically proven to be truly ergonomic, backed by 2.8 million data points.

Satin Steel™

Scaler Handle

Our Satin Steel™ Handle with diamond knurl pattern and large diameter handle provides a confident and comfortable grasp. Optimal weight reduces hand fatigue.

ResinEight™

Resin Scaler Handle

ResinEight™ Scaler handles provide a lightweight handle option with a color-coded system corresponding to anatomical areas of the mouth.

THE SCIENCE OF EVEREDGE 2.0

Who Tested the Instruments?

Independent testing was conducted by CATRA, a specialized blade laboratory. They evaluated HuFriedyGroup EverEdge™ 2.0 Scalers alongside four competitors’ instruments.

How Were the Instruments Tested?

The blade of each instrument was tested by repeatedly pushing it into a specially calibrated silicone test strip. The amount of force required to push the blade into the test media was measured in Newtons, a common international unit used to measure tension and shear force. The less force required to penetrate the media indicates a sharper blade. The blades of each instrument were also subjected to multiple strokes on the same calibrated test strip to simulate wear. These repeated strokes will begin to reduce the sharpness of the blade and therefore require more force to enter the test strip. After a predetermined amount of strokes is applied, the force to make the final cut is measured to determine the sharpness durability of the blade.

Why Do Some Instruments Get Sharper After Several Uses?

When there is a spike in sharpness, that is due to the burr formation on the product. A burr is a small flap of metal that actually covers the instrument’s blade. Burr formations occur when the finishing step is done too quickly — an indication of poor process control. EverEdge™ 2.0 Scalers do not have a burr formation due to our refined process and techniques.

The Most Advanced Scaler Ever

EverEdge™2.0 Scalers and Curettes are the sharpest and longest-lasting instruments for your clinical procedures. Learn more about why these instruments are better than ever.

Can’t get enough EverEdge™ 2.0 Scalers & Curettes?

With so many patterns and handle options to choose from, HuFriedyGroup has the specific scaler for every procedure, every patient, every day.